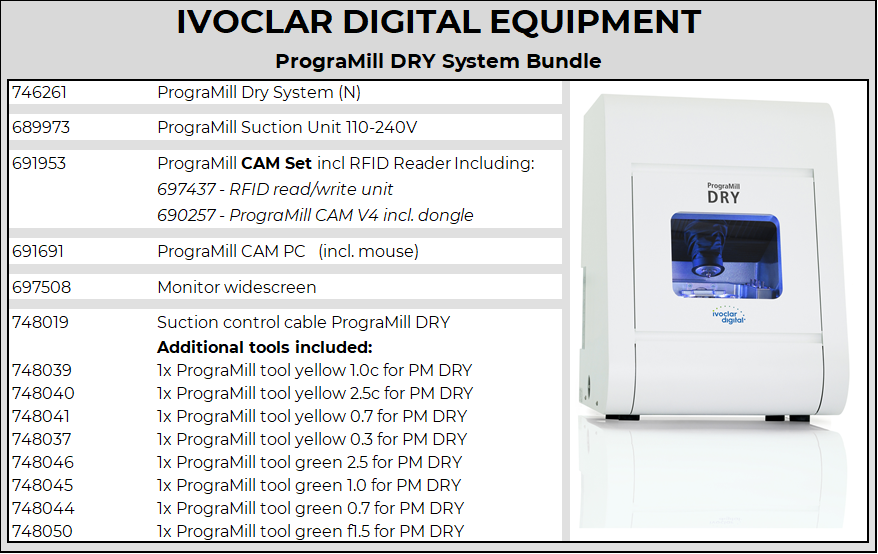

PrograMill Dry System

DEAL INCLUDES:

Dental laboratories are looking to mill zirconia restorations safely and efficiently in-house will find the new PrograMill DRY milling unit from Ivoclar Vivadent the ideal gateway, The CAD/CAM dry milling unit us a sophisticated system solution in a compact design that combines coordinated processes with high quality materials, mature technologies and comfortable handling.

Milling zirconium oxide professionally: this call inspired Ivoclar Vivadent to extend its portfolio to include the PrograMill DRY 5-axis dry milling unit.

The mill is a robust entry-level unit designed for the cost-efficient production of restorations made of zirconium oxide as well as a variety of PMMA material (e.g. Ivotion for complete digital denture prosthetics).

Precise and flexible: designed for zirconia restorations and Ivotion dentures

The PrograMill DRY is ideally suited for milling IPS e.max ZirCAD Prime discs, enabling laboratories to optimize their cost effectiveness and efficiency. These innovative zirconium oxide discs from Ivoclar Vivadent offer impressive esthetic properties and a maximum range of processing options, including staining, cut-back and veneering techniques. The material is suitable for all restoration designs, ranging from crowns to multiple-unit bridges. The exceptional quality and esthetic properties of this zirconium oxide results from the innovative Gradient Technology employed to manufacture the discs. In addition, the PrograMill DRY unit is also suitable for the CAD/CAM production of complete dentures using the Ivotion denture system. The Ivotion Denture Holder enables the Ivotion CAD/CAM disc to be placed in the exact position in the machine for performing the milling process. Ivotion and PrograMill DRY can be used together to produce complete monolithic dentures in a single milling operation using a digital workflow.

Reliable and efficient – a coordinated process

The PrograMill DRY unit is fully integrated into the Ivoclar Digital workflow, offering dental laboratories a straightforward and cost effective manufacturing process. Laboratories that are new to the field of automated manufacturing will benefit especially from the perfectly coordinated process components. The PrograMill CAM software provides dental technicians with an intelligent software application that enables a high level of process reliability and time savings

Compact and convenient – effortless handling

With its compact design, the PrograMill DRY easily fits in any laboratory and can be ideally placed even in a small room where space is at a premium. The milling machine offers dental technicians many practical features. For instance, the quick clamping system enables an effortless change of materials: the CAD/CAM discs can be intuitively and conveniently replaced using just one hand. No additional tools required. This makes it easy to operate the machine.

|